Expert Engineering

We Realize What Others Only Sketch

Leading mechanical engineering and software solutions in automation and robotics

Automation

Advanced automation solutions for modern industry

Innovation

Cutting-edge technology for tomorrow's challenges

Efficiency

Streamlined solutions that maximize your project outcomes

Engineering Services & Capabilities

Comprehensive solutions combining mechanical precision with cutting-edge software technology to drive innovation in process automation and robotics

Additional Capabilities

Specialized services that complement our core engineering offerings

Turnkey Solutions

Complete solutions from design to deployment - we handle it all

Digital Twin Development

Virtual representations for testing and optimization

Maintenance Solutions

Predictive maintenance and support services

Project Management

We manage your project from start to finish

Project Portfolio & Case Studies

Discover how we've transformed operations for leading companies through innovative automation and robotics solutions

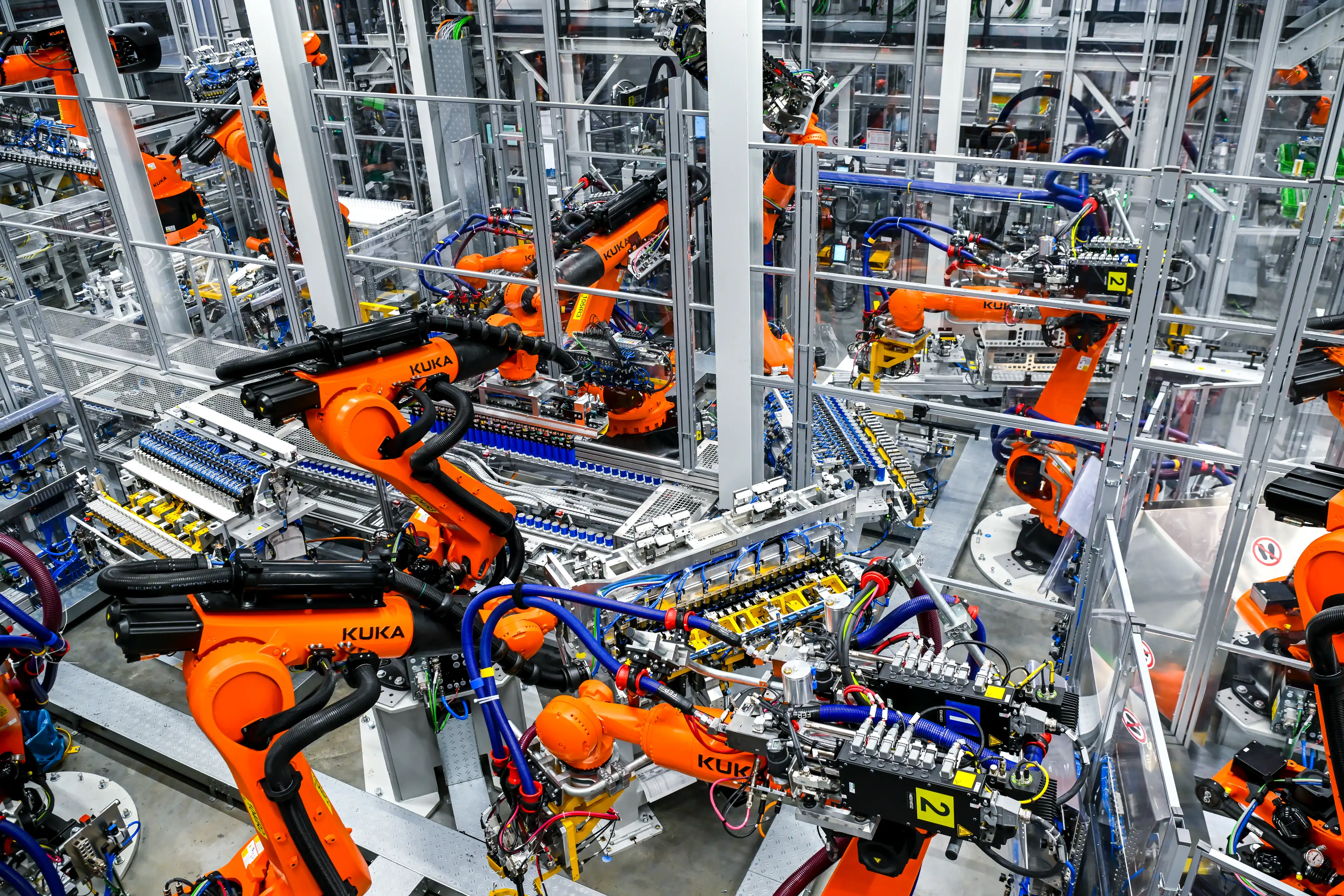

Pilot plant and subsequent series plant for the automated assembly of battery modules.

Challenge:

Planning and design of a highly flexible system that can produce a variety of different models without modifications, and later linking all stations with a conveyor belt in the series plant.

Solution:

Delivered flexible production cells with over 40 robots, including heavy-duty robots, intelligent conveyors, and process simulation — modular, reconfigurable, and ready to meet future manufacturing demands.

Key Results:

Technologies Used:

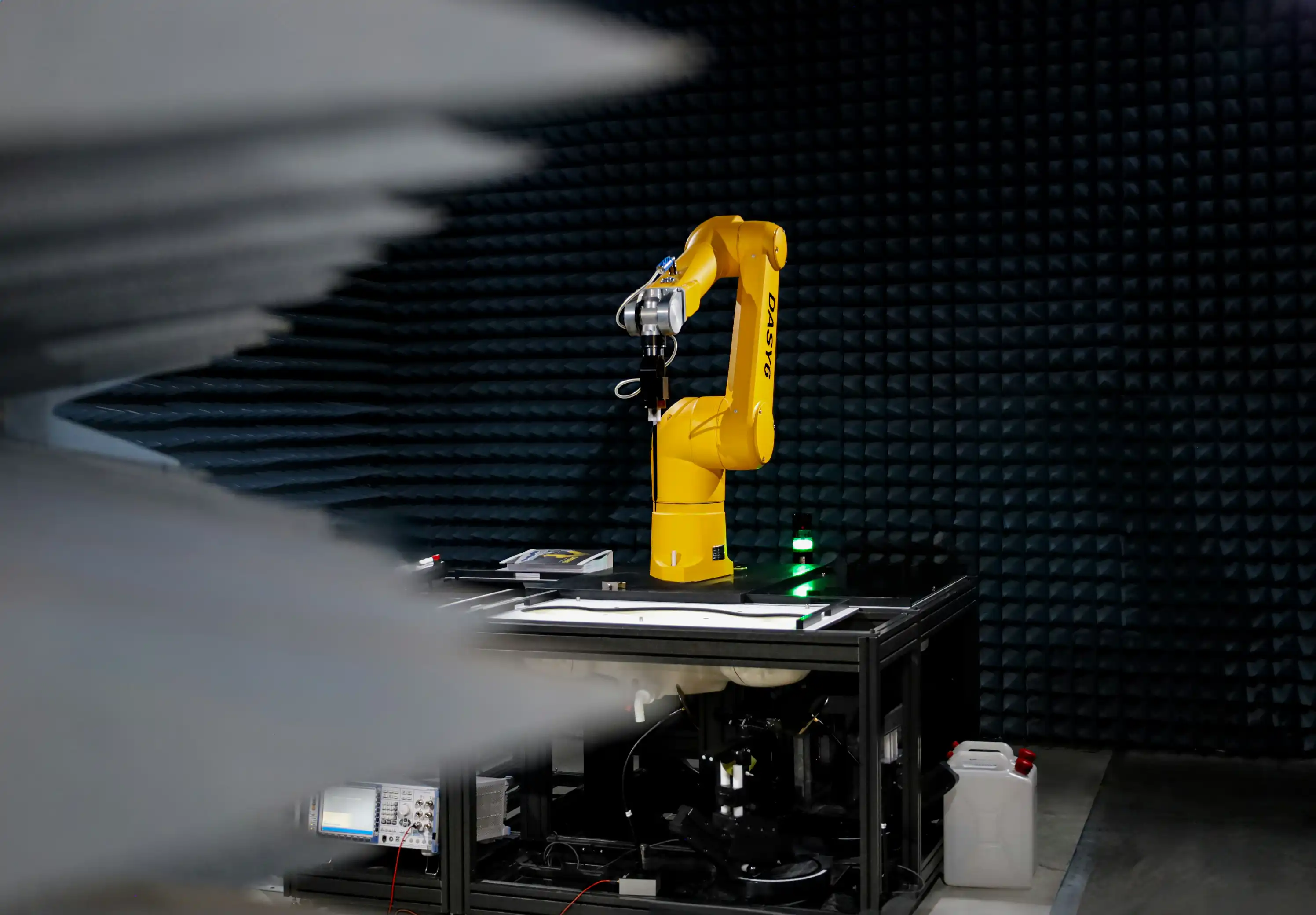

Development of a semi-automated robot cell for disassembling battery modules from automotive applications.

Challenge:

Development of a test cell where battery modules can be disassembled using robot-guided milling. Before automated milling, the battery must be completely scanned to determine optimal milling paths based on the obtained coordinates.

Solution:

Implemented robot-guided milling cycles with adaptive path planning in real-time, constructed a turning device for secure workpiece handling and complete processing from all sides, developed mobile transport carts for flexible handling, and established comprehensive safety concept including explosion protection and CE documentation.

Key Results:

Technologies Used:

Logistics portal for simplifying communication between producers and sellers while supporting order picking processes.

Challenge:

Development of a user-friendly portal to optimize logistics processes between agricultural producers and sales, with integration into existing systems and databases.

Solution:

Implementation of a modern web application with Svelte frontend, PostgreSQL database, Auth0 authentication, and Tailwind CSS for responsive design. The portal has been running successfully for 1.5 years and will continue for at least another year.

Key Results:

Technologies Used:

Web-based remote maintenance solution for monitoring and controlling MyAppCafé Boxes - autonomous robotic coffee bars that serve fresh coffee drinks. Leverages AWS IoT for real-time job execution and status updates.

Challenge:

Create a unified interface to streamline administration tasks by integrating multiple existing services including ERP system, camera feeds, and voucher systems into a single, easy-to-use web application while providing real-time job execution capabilities.

Solution:

Developed a modern web application using Svelte 5 with TypeScript, Tailwind CSS for styling, and Docker for containerization. Integrated AWS IoT for real-time remote job execution and status updates, enabling administrators to monitor and control robotic coffee bars in real-time. Implemented comprehensive testing with vitest and CI/CD pipeline with GitHub Actions for automated deployment.

Key Results:

Technologies Used:

Ready to Start Your Next Project?

Let's discuss how we can transform your operations with cutting-edge automation and robotics solutions

Our Engineering Team

Meet the leadership and discover the comprehensive expertise that drives FxB Engineering's innovative automation and robotics solutions.

Leadership

Our co-founders bring together the perfect blend of mechanical precision and software innovation

Norbert Fischer

CEO & Co-Founder

Mechanical Engineering

Leading mechanical engineering expert with 15+ years in automotive industries. Expertise in project management, rapid prototyping, machine safety, manufacturing processes, process optimization and has led numerous automation projects across Europe.

Certifications:

Frank Bielecke

CEO & Co-Founder

Software & Cybersecurity

Pioneering software architect specializing in industrial applications, with a focus on cybersecurity. Expertise in Cloud Architecture, robotics software, and real-time control systems.

Certifications:

Engineering Capabilities

Our specialized team brings deep expertise across all aspects of modern automation and robotics

Robot Programming

Expert programming for industrial robots including ABB, KUKA, and Universal Robots

Technologies & Tools:

3D Printing & Additive Manufacturing

Advanced additive manufacturing solutions for rapid prototyping and production

Technologies & Tools:

2D Layout & Technical Drawings

Precise technical documentation and manufacturing drawings

Technologies & Tools:

Electronics & Control Systems

Custom electronics design and industrial control system development

Technologies & Tools:

Mechanical Engineering

Comprehensive mechanical design and analysis capabilities

Technologies & Tools:

Pneumatics & Fluid Power

Pneumatic and hydraulic system design for automation applications

Technologies & Tools:

Ready to Work with Our Expert Team?

Our comprehensive expertise ensures your automation and robotics projects are delivered with precision and innovation

Start Your Project

Ready to transform your operations? Share your project details and our experts will contact you within 24 hours with a customized solution proposal.

info@fxb.engineering

Phone

+49 160 1669894

+49 160 1135268

Address

FxB Engineering GmbH

Lotzbeckstr. 9

76185 Karlsruhe, Germany

HRB 752205

Business Hours

Monday - Friday: 8:00 - 18:00

Saturday: 9:00 - 14:00

Emergency Support: 24/7

Loading security token...